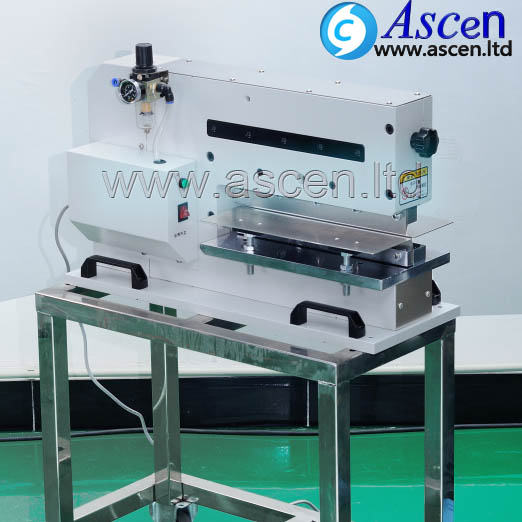

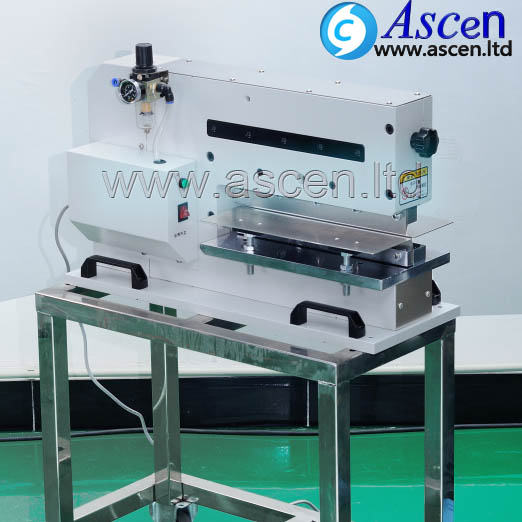

1. V-cut depaneling machine For internal strength generates during separation, Minimize it to value under 180uE ,to avoid solder crack or component damage

2. Able to depanel PCB edge of V-slot, minimum distance to component is 0.5mm,and max height of component is 60mm

3. Free sanding on Blade when it is worn.

4. PCB depaneling speed is one cut per second, controlled by pneumatic foot-plate switch

5. Blade activated negative, separation route and position in control safely

6. Pneumatically driven and electric control

7. PCB separation is not realized by friction, so no obvious metal residue left,

8. V-cut Depaneling life is over 6000000 times

9. Air pressure 6 to 8 kg, no requirement on working environment, simple maintenance by anti-rust oil

10. Guillotine type V-cut depaneling machine for Aluminum LED Board and FR4 Board

ASCEN as a PCB separator manufacturer provide the full SMT manufacturing equipment, producing different type PCB depaneling machine, include the blade moving type V-cut PCB separator, cutting disc type PCB cutting separator , Pneumatic cutting type PCB separator , Aluminum PCB separator , PCB punching separator , manual pcb separator, PCB depaneling router, Multi cutter PCB cutting machine are available as standard and customized products and can be equipped to fit special requirements

|

Subject |

Parameters |

Model No

(PCB cutting machine) |

ASC-620 |

|

Max Cutting Length |

330mm |

|

Cutting Thickness |

0.5 to 3.5 mm |

|

Working Pressure |

0.6 to 0.8 Mpa , dry air source |

|

Max Height of Component |

50mm |

|

Equipment Dimension |

700*550*460mm |

|

Working Voltage |

AC 220V 50~60HZ |

|

Gross weight |

120KG |